Whilst working on a corset and sewing the stay channels, I lamented that my chalk lines were simply too wide and caused too much variance. I thought back to the days my mother first taught me to use a sewing machine. She, after removing the thread and bobbin, had me sew a piece of lined paper to get the hang of the machine. If I could sew a straight line along the printed lines then I could use thread in the machine. (Thanks mom! I still use this method when teaching others to use the sewing machine!)

Then it occured to me that a friend of mine showed me how to spray glue a piece of paper, with the desired design printed on it, to a piece of fabric. Then sew through the paper and fabric following the printed design. Afterward remove the paper and viola! More perfect a design you can not find! (Thanks Lynnette! I can certainly learn from others, and I am thankful for this idea!)

|

| The paper with stay channels glued in place |

STEP 1: I went to the computer and worked out markings slightly larger than 1/2". I used a "]" at the regular intervals both at the top and bottom of the page (I used landscape for the page options). Then printed. *

STEP 2: I marked the corset pattern with using the printed guide from step 1. I then connected the matching lines with a ruler. ** I had already drafted my corset pattern and cut the fabric, but because this was an afterthought method, the draft was only half. Now I will draft my corset patterns as full patterns**

STEP 3: In my bath tub, I placed the fabric pieces, already spray glued together, and then spray glued the top piece of fabric. Working carefully, I placed the paper pattern on the top-- making sure it lay as perfectly as possible.

|

| Step 4 Sewing through the paper and fabric |

STEP 4: I sewed through the paper and fabric along my lines.

|

| Step 5 Removing the paper-- went to water method |

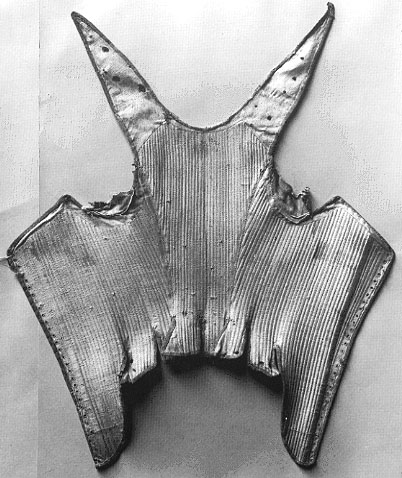

ALL DONE! Yea! I was pleased. When using my older method , the stay channels weren't as even and straight as I would like. This new method produces a much more uniform product.

* I use double the stays when I create a corset so the channels need to have enough room to accommodate the depth of two stays.

Warmest Regards,